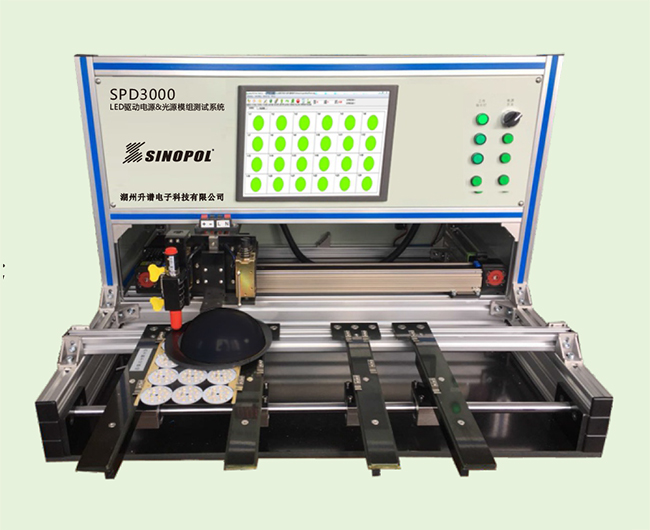

An intelligent mechanical arm, a precision photometric sampling device, a V (lambda) analog human eye probe, an input and output electrical parameter tester and an industrial control computer are integrated.

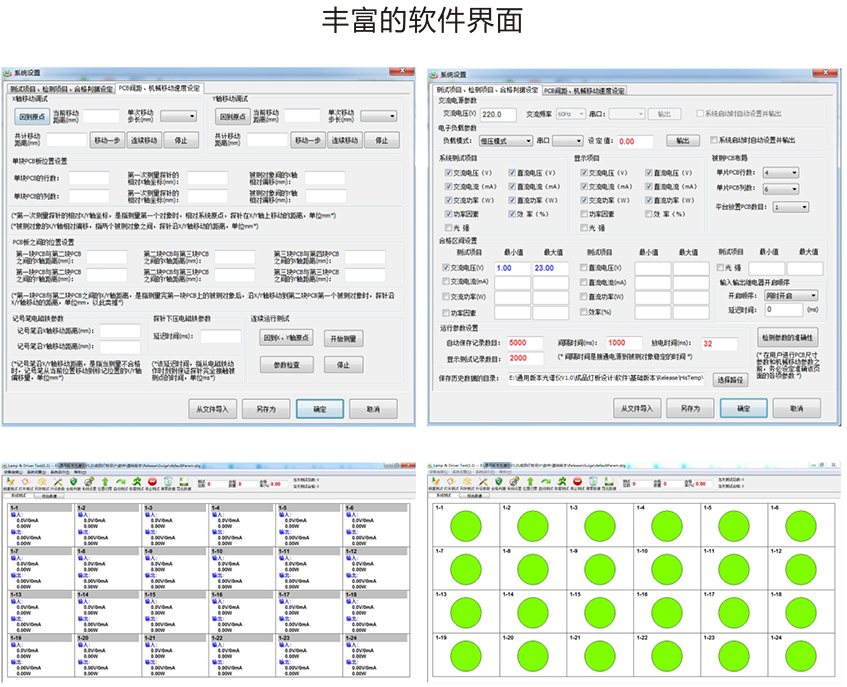

First, fast and accurate measurement of the input voltage, input current, input power, input power factor, output voltage, output current, output power and energy efficiency of LED drive power supply.

Two. Quickly and accurately measure the lighting of the LED light source module. It can be judged according to the preset electrical parameters and the lower limit of the light parameters. The unqualified automatic marking is made and the total number of tests and the total number of unqualified are kept. Convenient and quick. All test data are automatically saved and conform to ISO9001 quality system requirements.

Three, suitable for finished PCB circuit board functional testing, efficient and accurate, reduce costs.

Equipment characteristics:

1. Test drive, the capacity is about 3000-5000pcs/h

Test module: the capacity is about 5000-8000pcs/h;

2, the instrument automatically determines whether it is qualified or not, and automatically marks it.

3, save all the test data automatically.

4. The test parameters are comprehensive and with discharge function.

5. The protection circuit of the fuse.

Technical indicators:

The 1. machine can test the input voltage, input current, input power, input power factor, output voltage, output current, output power, energy efficiency, brightness and other parameters. It can set up the upper and lower limits of the test parameters, which will automatically mark the bad product below or beyond the set range.

3. three operation stations can choose different workstation tests according to actual production needs.

The 4. workstation has automatic cycle test and manual input signal test, and the operation is more flexible.

5. different test procedures can be set according to different PCB boards, and the position of the PCB board can be adjusted by width.

6. the machine can set mechanical parameters, test time, upper and lower limits, and discharge time.

7. changing the different test and adjusting the corresponding measurement and control documents;

8. the machine automatically records the number of qualified, unqualified, total number of tests, and pass rate.

9. open software design, easy to customize and upgrade.

10. power requirements: AC220V, reliable grounding;

11. the precision of input and output test: 0.3%;

12. photometric accuracy: first class;